AAC Autoclave for aac block making equipment

Product Description

AAC Autoclave for aac block making machine

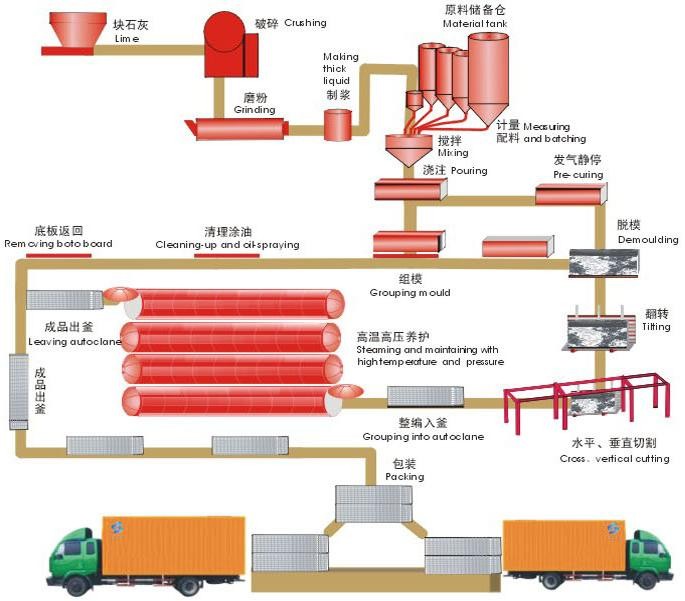

AAC/Autoclave Aerated Concrete Block Machine production process

The Process of manufacture is simple t follow, and complex to implement.

First, the Fly Ash is mixed with water, and made Slurry in a slurry mixture. If Sand is used as a base material, we need a ball mill to grind the sand to fine power. The slurry making process is same sand.

After Slurry is made, the slurry is stored in slurry storage tank, where the slurry is constantly agitated. Care is taken to run the slurry storage tank all the time, so that is never settles down the particles.

Then a weigh batcher weighs the Slurry, lime, OPC, Gypsum and aluminum power in preset quantities, and mixes thoroughly. The mixture also pours the mix into the Mould carried n the mould cart. The full pouring of the mixture is just enough to fill around 50% of the mould.Then the mould is kept in a warm chamber for 2 hours, so that the aeration and the light initial setting takes place. Next process is demolding process of the big block, in which a sophisticated overhead hoist takes the mould, demoulds the block.

Next process is the level wire cutting of the Block, while the block passes on the cutting trolley through the series of wires. This process follows a vertical wire cutting where as the block remains stationary, and th

Autoclave is the pressure vessel and key equipment in the production of aerated concrete and autoclaved brick. It is applicable for curing the cut body or brick under high temperature and high pressure. The working medium is saturated water vapor.

The main parts are made by autoclave body, cover, hand-operated reducer, safe blocking device, support saddle, valve meter etc. The body is a principle and cylindrical device made of steel. The cover is made of a whole piece of pressed 16MnR steel board, and the flanges of cover and body adopt a whole piece of forged and processed 16Mn steel board.

The welding lines of pressed components are subjected to heat treatment and strict nondestructive test.

Autoclaved aerated concrete block material based on calcium and silicon as the basic components to the formation of porous gas method of chemical hair structure,obtained by autoclaved curing of high strengh ligh weight artificial stone. It can be said of autoclaved aerated concrete block is a chemical made by a special method of gas gas autoclaved porous silicate concrete.currently,autoclaved aerated concrete block product is the highrise building frame structure of various raw materials,no other product can substitute for its future in the ascendant,there is no risk of product,process maturity,will not lead to investment risk,the product also conforms to national industrial policy.Development of the autoclaved aerated concrete block is one of the important measurea China wall reform can save a lot of land,a lot of energy,but also turing waste into wealth,cleaning up the environment ,reduce pollution,both good economic benefits as well a significant social benefits.

1 The operation of our plant is simple and practical.

2 Waste materials and water can be recycled during operation process, it is environment-friendly.

3 The whole equipment has higher degree of automation.

4 The final products are high in precision, qualified product rate ≥ 98%.

5 JTM AAC plant has good cost performance.

Factory Price AAC Brick Manufactureing Plant Autoclave Aerated Concrete Block Machine For Sale working Principle

1) Technology Orientation

Production and application of aerated concrete has a history more than 40 years in China. Viewing from technology point, high quality products can use 3mm special sand slurry technology to meet the construction requests and 50% energy saving goals. (When mortar joint is less than 3mm, take thermal conductivity coefficient of wall as 1; when mortar joint is more than 3mm, take thermal conductivity coefficient of wall as 1.5). Based on the history of the aerated concrete development, only high quality products can bring a prosperous market. Thus, the technology orientation of this scheme is high-class products according to China Standard GB11968-2006.

2) Production Capacity

In our factory, the main production capacity is annually 50,000m3, 100,000m3, 150,000m3, 200,000m3, 300,000m3 etc. The product is aerated concrete block which is light in weight. Also, there is a reservation of plate in consideration of users' need.

3) Product Specification

Products conform to requirement of 04~07 grade blocks stated in GB11968-2006.

General Specifications of Aerated Concrete Blocks

Areated concrete block (light block ) is the light and porous buidling material. It has light keeping temperature cant burn and other advantages. It can be made into many kinds of bricks for example: 600× 200× 100, 80× 80× 180, 240× 115× 53, 600× 200× 125), they could be used industry building and common building. They are more and more popular in the world. In the future, they will replace the Clay brick completely.

Areated concrete common conception Common concrete density is usually 1600-2400kg/m3, but Areated concrete are 500kg/m3, 600kg/m3, 700kg/m3. It has not the big grain, main use silicon material (for example: Coal ash, sand, stone dust and others ), through making the material small for example sand, they can be used directly if has enough degree of small (for example coal ash. Mixing calcium material lime cement water to a special slop, then add the aluminum dust and the additive. Make the aluminum dust and the special slop have a Chemical reflect. Then produce Hydrogen to make the concrete slop to expanding or swell, foam. Next, put them into the curing room to concreting cutting steaming curing, last, there will bacome the light brick, the porous rate is 70-80%.

2. AAC Block Machine, AAC Production Line, AAC Plant, Light Weight Block Production line common sense:

1. Light weight, Areated concrete density is usually 400-700kg/m3, (according the market in produce ), same as 1/3 of clay block and 1/5 common concrete. So use the Light block can reduce the weight of the build more, and also reduce the beam of roof and pillar press best. Then you can see, it can save the material and cost, it also fighting shaking.

2...Keeping temperature It has many are porous, the delivery hearting coefficient is 0.9-0.22W/(mk), the same as 1/4 or 1/5 of clay brick, so it is best materials now in the world.

Have many kinds material, have lowest waste

Main Material: Coal ash sand waste mine material coal stonestone dust and other silicon materials.

(1 )Product weight is according to 600kg/m3 to control. (2 )annual capacity 200, 000M3. (3) set raw material proportion: Cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

(4) water and material rate 0.631 (5) one mould product 2.88M3 (6) Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes. (7) casting slurry temperature 38-42 degree

(8) body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

(9) Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

(10). Cement lime fly ash style aerated block raw material proportionName unit Cement lime fly ash

Flash % 65-70 Cement % 6-15 Lime % 18-25 Gypsum % 3-5

Aluminum powder paste(600kg/m3) 1/10000 8 Water & material rate 0.60-0.65 Casting system OC 36-40

Aluminum mixing time S 30-40

(11). Cement lime Sand style aerated block raw material proportion

Name Unit Cement Lime Sand Sand % 55-65 Cement % 10-20 Lime % 20-30 Gypsum % 2-3

Aluminum powder paste(600kg/m3) 1/10000 8 Water & material rate 0.65-0.75

Casting system OC 35-38 Aluminum mixing time S 30-40

Reference: Cement is 42.5 Portland or 42.5 common cement

| 1. Sand 69% | ||||

| Super Grade | First Grade | Qualified product | ||

| SiO2 | ≥ | 85% | 75% | 65% |

| CI- | 0.02% | 0.03% | 0.03% | |

| Mica | ≤ | 0.5% | 0.5% | 1% |

| S O3 | ≤ | 1% | 1% | 2% |

| clay | ≤ | 3% | 5% | 8% |

| K2 O+Na 2O | ≤ | 1.5% | 3% | 5% |

| 2. Lime 20% | ||||

| Item | G aerated concrete blocks,aerated concrete blocks equipment,aerated concrete brick(light brick) DONGYUE rade | |||

| Super Grade | First Grade | Qualified product | ||

| A(CaO+MgO) Quality Fraction % | ≥ | 90 | 75 | 65 |

| MgO Quality Fraction % | ≤ | 2 | 5 | 8 |

| SiO2 Quality Fraction % | ≤ | 2 | 5 | 8 |

| CO2 Quality Fraction % | ≤ | 2 | 5 | 7 |

| Digestion speed ,min | ≤ | 5-15 | ||

| Digestion temperature , °C | ≥ | 60-90 | ||

| Undigested residue quality fraction ,% | ≤ | 5 | 10 | 15 |

| Fineness ( 0.080 square hole sieve left amount) % | ≤ | 10 | 15 | 20 |

Product Categories : AAC Autoclave